With the evolving need for environmentally-conscious foam proportioning equipment, learn about FireDos proportioners‘ design and operating principles when specifying them in your customer‘s special hazards applications.

News

The results of the bvfa's statistics prove: Stationary extinguishing systems with automatic activation are effective. Learn more

April 25, 2024

Product News

The FireDos ECO proportioners impress with proven quality at an extremely favourable price. Available from stock! Learn more

April 16, 2024

News

Are you looking for high-quality extinguishing technology with short delivery times? Discover the FireDos marketplace! Learn more

March 15, 2024

We ensure safety through firefighting with foam.

FireDos specializes in the development and production of innovative and reliable proportioning systems, extinguishing monitors and trailers for firefighting. We provide our customers security through risk reduction, lower operating costs and compliance with legal regulations. Every single

FireDos product is designed, built and tested

to meet the most challenging conditions. Our proportioning systems, extinguishing monitors and trailers fulfill an elementary task: they protect people, buildings, plants and equipment.

You are interested in our products?

We will be happy to help you along. Request a non-binding quotation from us!

The FireDos newsletter always keeps you well-informed. Stay up-to-date on all aspects of fire extinguishing technology.

FireDos stationary proportioners are installed in sprinkler or deluge, wet or dry extinguishing systems. Typical applications include sites where flammable liquids/substances are produced, transported, stored or disposed, e.g., in fire extinguishing systems for tank farms, jetties, hangars, high-rack warehouses or pump rooms.

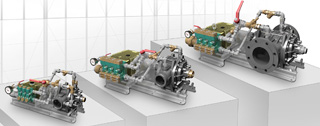

Designed specifically for municipal, volunteer and industrial fire departments, FireDos fire apparatus proportioners are installed within the fire truck and produce extinguishing foam or wetting agent.

FireDos portable proportioners are optimized for varying firefighting scenarios and provide maximum flexibility. Capable of producing extinguishing foam or wetting agent, FireDos portable proportioners are designed for pulsating/intermittent use and are suitable for all nozzle types.

FireDos monitors can propel water 500 feet at a rate exceeding 15,000 gpm and are designed for water or foam firefighting scenarios. Various nozzle types are available.

FireDos fire trailers provide unparalleled on-site flexibility and can be equipped with monitors and/or proportioners.

We support our customers before, while and after the purchasing process. Acting globally, we enable local support at any stage of our cooperation. Nimble service, target oriented communication and smooth transition of all project phases are self-evident for us.

Every project is unique and requires its own approach. This is how we find solutions which are perfectly tailored to suit our customer's requirements.

Daily work at FireDos is inspired by the idea of being a team. Any mistake will just help us to develop further. We celebrate success together and thrive as our tasks grow.

We stand by our word and decisions. Being reliable is elementary to us. No matter if customer, sales partner or association: our business relationships are characterized by fair, appreciative and respectful interaction.

Our special focus is on continuous enhancement of our product groups: proportioners and monitors. We work permanently to find new even more efficient solutions. Our technology is developed and manufactured in-house. Doing so, satisfying our customer's needs is our highest goal.